Essential Maintenance for Audi 5 Cylinder 10V Turbo Valve Shims

If you’re an Audi enthusiast or just love tinkering under the hood, you know that the 5-cylinder 10V turbo engine is a legendary powerplant. Its unique sound, smooth power delivery, and incredible reliability have made it a fan favorite. But there’s a small, often overlooked component that plays a big role in keeping these engines running perfectly: valve shims.

In this guide, we’ll break down everything you need to know about Audi 5 cylinder 10V turbo valve shims—what they are, why they matter, how to maintain them, and tips to keep your engine performing at its best.

What Are Valve Shims?

Think of valve shims as the unsung heroes of your engine. These tiny, precisely machined discs sit between the camshaft lobes and the valve lifters (or tappets). Their job? Adjusting valve clearance so that your valves open and close at exactly the right times.

In overhead cam engines like Audi’s 5-cylinder turbo, correct valve clearance is essential. It ensures:

-

Smooth valve operation

-

Optimal combustion

-

Reduced engine wear

Without the right valve shims, even a small gap issue can ripple into major performance problems.

Why Valve Shims Matter in the Audi 5-Cylinder 10V Turbo

Valve shims aren’t just technical jargon—they directly affect your engine’s health and performance. Proper valve clearance impacts:

-

Engine Performance: Precise timing allows efficient airflow and combustion, giving your engine the power and smoothness it’s known for.

-

Longevity: Correct clearance prevents unnecessary wear on your valvetrain components.

-

Noise Reduction: Incorrect clearance can produce tapping or clicking noises that ruin the serene hum of your turbo engine.

-

Fuel Efficiency: Poor valve operation leads to incomplete combustion, which means more fuel consumption.

In short, valve shims are small but mighty—keep them in check, and your Audi will thank you.

Signs Your Valve Clearance Might Be Off

Even the best engines experience wear over time, and valve clearances can drift, which is where problems start. Look out for these common symptoms:

-

Tapping or Clicking Noises: Loud, rhythmic sounds from the engine often signal excessive valve clearance.

-

Loss of Power: Uneven valve operation affects combustion, resulting in reduced horsepower.

-

Rough Idling: Your engine may feel unstable or uneven at idle.

-

Increased Fuel Consumption: Improper combustion can eat more fuel than necessary.

-

Engine Misfires: Bad valve sealing can lead to misfiring cylinders, especially under load.

Catching these issues early can save you from costly repairs down the line.

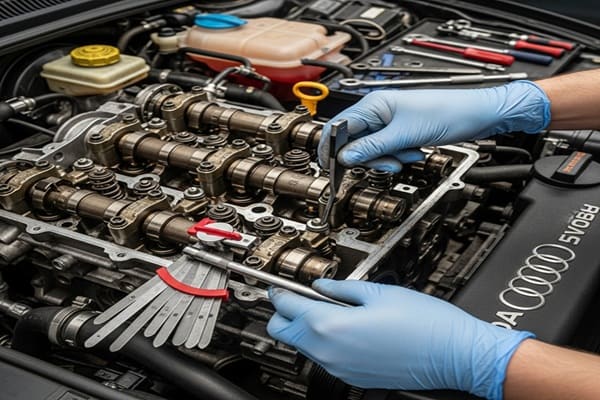

How to Maintain and Adjust Valve Shims

Regular maintenance is key to keeping the Audi 5-cylinder 10V turbo engine performing like new. Typically, valve clearances should be checked every 60,000 miles or according to your owner’s manual.

Here’s a friendly breakdown of what you need and how to do it:

Tools You’ll Need

Before you dive in, gather these essentials:

-

Feeler gauges (for measuring valve clearance)

-

Valve shim tool (for removing and installing shims)

-

Micrometer or digital caliper (for precise measurements)

-

Replacement shims

-

Torque wrench (for proper reassembly)

Having the right tools is half the battle. It ensures accuracy and prevents mistakes that could damage your engine.

Step-by-Step Valve Shim Adjustment

Adjusting valve shims may sound intimidating, but with patience and the right approach, it’s very doable. Here’s a clear step-by-step:

-

Prepare the Engine – Always start with a cold engine to get accurate measurements.

-

Remove the Valve Cover – Carefully remove it to access the camshaft and lifters.

-

Measure Valve Clearance – Use feeler gauges to check the gap between the camshaft flanges and valve lifters.

-

Determine Required Shim Thickness – If the clearance is off-spec, calculate the thickness needed for correct adjustment.

-

Remove Old Shims – Use the valve shim tool to safely extract worn shims.

-

Install New Shims – Insert shims of the correct thickness to achieve the specified clearance.

-

Recheck Clearance – Always verify the clearance again to ensure precision.

-

Reassemble the Engine – Replace the valve cover and reconnect any components. Start the engine and listen for smooth operation.

Following these steps carefully ensures your engine runs quietly, efficiently, and at peak performance.

Choosing the Right Valve Shims

Not all shims are created equal. When picking replacements:

-

Stick to Manufacturer Specs: Use the clearance values provided for your specific Audi model.

-

Prioritize Quality: High-quality shims last longer and maintain proper clearance.

-

Avoid Reusing Worn Shims: Old shims may have uneven wear, which could throw off your adjustment.

Valve shims usually come in increments of 0.05mm, so accuracy matters. A tiny miscalculation can affect performance and fuel efficiency.

Common Mistakes to Avoid

Even experienced enthusiasts can slip up. Avoid these pitfalls:

-

Skipping Regular Inspections: Delaying checks can lead to bigger, costlier problems.

-

Incorrect Shim Thickness: Always measure and calculate before installing.

-

Not Rechecking After Installation: Verification is crucial to avoid guesswork.

-

Over-Tightening Components: Use a torque wrench to prevent damage to valves or camshafts.

Remember, precision is the name of the game.

How Incorrect Valve Clearance Affects Performance

It’s more than just annoying noise. Poor valve clearance can:

-

Reduce power output due to inefficient combustion

-

Cause misfires and uneven engine operation

-

Increase fuel consumption, hitting your wallet at the pump

-

Lead to premature wear of expensive engine components

Maintaining correct valve clearance isn’t optional—it’s essential for keeping your 5-cylinder turbo engine healthy.

The Benefits of Routine Valve Shim Maintenance

Keeping your valve shims in top condition ensures:

-

Smooth Power Delivery: Engine runs quietly and efficiently.

-

Extended Engine Life: Prevents unnecessary wear and tear.

-

Optimal Fuel Efficiency: Correct combustion keeps fuel use in check.

-

Peace of Mind: Reduces the likelihood of sudden breakdowns or expensive repairs.

For Audi enthusiasts, this is the difference between a good engine and a legendary one.

Conclusion

Valve shims may be small, but in a 5-cylinder 10V turbo engine, they are a crucial piece of the puzzle. Regular inspection and adjustment:

-

Preserve engine performance

-

Prevent noise and misfires

-

Maintain fuel efficiency

-

Extend the life of your valvetrain

Using the right tools, following proper procedures, and choosing high-quality shims ensures your Audi keeps delivering that iconic turbo roar and smooth driving experience.

Whether you’re a seasoned mechanic or a dedicated DIY enthusiast, understanding Audi 5-cylinder 10V turbo valve shims is a step toward mastering your engine and keeping it performing like new.

FAQs About Audi 5-Cylinder 10V Turbo Valve Shims

Q: How often should I check and adjust the valve shims?

Typically, every 60,000 miles, or as recommended in your owner’s manual. Regular checks prevent premature wear and ensure peak performance.

Q: What are the signs of incorrect valve clearance?

Listen for tapping or clicking noises, loss of power, rough idle, higher fuel consumption, or misfiring cylinders.

Q: Can I reuse old valve shims?

It’s best to use new, correctly sized shims. Reusing worn ones can compromise accuracy and performance.

Q: What tools are needed for adjustment?

Feeler gauges, a valve shim tool, micrometer or digital caliper, replacement shims, and a torque wrench.

Q: How does improper valve clearance affect fuel efficiency?

Incorrect clearance causes inefficient combustion, increasing fuel consumption and reducing engine performance. Proper adjustments maintain optimal efficiency.